Liquid / Fluid Fillers

From oil to water, sauce to soap, we can fill it!

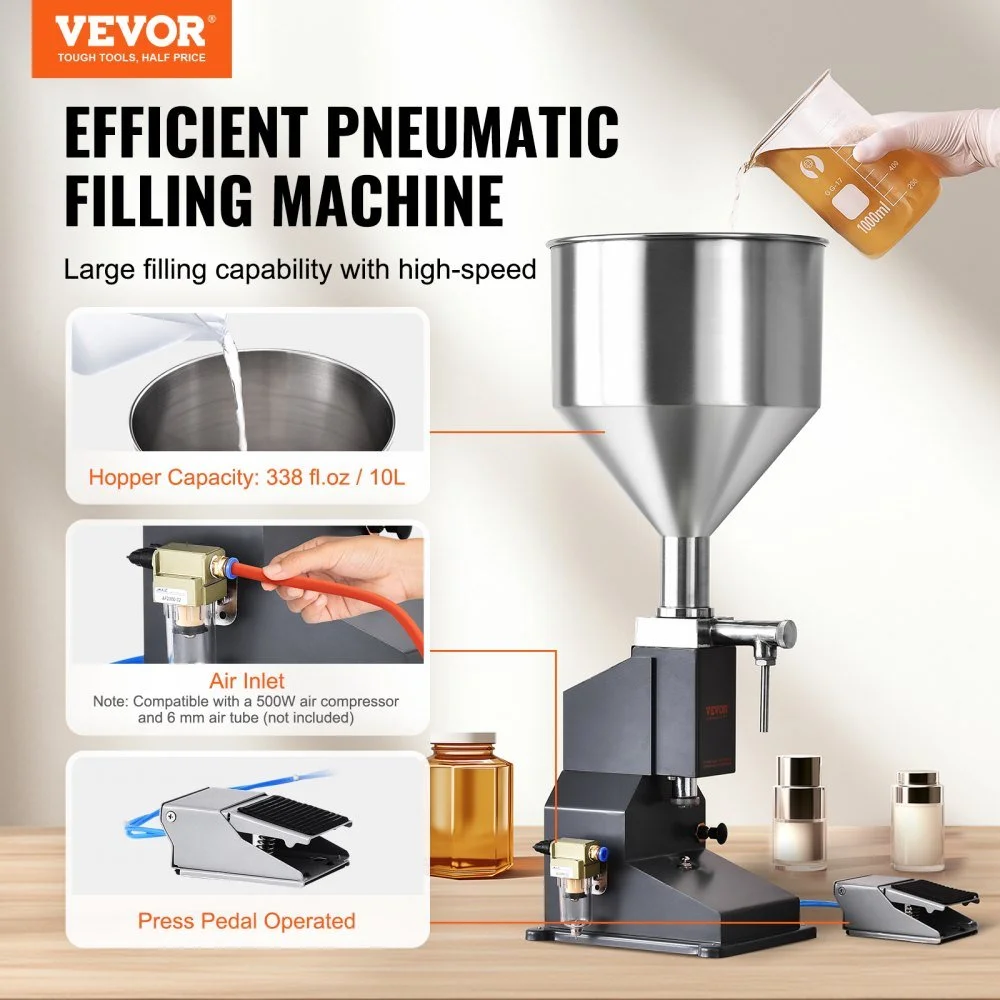

Vevor Tabletop Filler (50ml Max)

Affordable but capable filler for small containers

Features & Details

Efficient Pneumatic Filling:

The pneumatic filler from Vevor operates using an external 500W air compressor and is controlled via a foot pedal, allowing for smooth, hands-free operation. While the operator switches containers, the pedal activates precise and consistent filling—streamlining the process from start to finish.

Precision Quantification:

Filling volume and speed are easily adjustable through a simple screw mechanism. This pneumatic liquid filling machine supports a range from 5ml to 50ml, providing flexibility for various applications. Once the desired volume is set, each press of the pedal delivers accurate and repeatable fills.

Food-Grade Construction:

Built with 304 stainless steel, this filling machine ensures durability and hygiene. The material is corrosion-resistant, capable of withstanding temperatures up to 392°F (200°C), and maintains purity by preventing chemical reactions with the product being filled.

Drip-Proof Design:

Each stainless steel dispensing nozzle is engineered for smooth, drip-free performance. The precision design includes anti-drip sealing rings on both the oil seal and nozzle, reducing mess and ensuring consistent, clean operation.

Versatile Performance:

The Vevor pneumatic filling unit is suitable for a variety of liquids and semi-liquids with good flow characteristics, such as honey, sauces, beverages, oils, shampoos, and similar products. Ideal for small-scale production, workshops, and home-based operations.

Note: Not recommended for extremely thick pastes.

Downloads

JoresTech Low-Viscosity Piston Filler

High-accuracy affordable piston filler 50ml - 5000ml

Available in the following sizes: 50ml, 100ml, 250ml, 500ml, 1000ml, 5000ml - Follow the link below to buy now!

This piston filler from Jores Technologies accurately measures and dispenses low viscosity liquids into a bottle or container. Designed to add efficiency to new or pre-existing manual production lines, the exact desired quantity of product is dispensed into a container with the simple push of a foot pedal. Highly versatile and effective, this machine is ideal for the cosmetic, food service, chemical, pharmaceutical, and personal care industries, among others.

Features:

316 Stainless Steel: Parts in contact with product are 316 SS.

304 SS shell.

EASY PROGRAMMING: Easy to use machine, utilizes a simple twist-knob to set liquid dispensing volume.

ACCURATE DISPENSING: Prevent leaks, under-pours, and over-pours by setting the exact amount of liquid that you wish to dispense per fill.

EASY TO CLEAN: Easy to take apart with a stainless steel build for easy sanitation.

BUILT TO LAST: Strong, corrosion-resistant stainless steel build.

COMPACT: Small machine that offers big solutions!

NO-DRIP NOZZLE: Bottom-closing filling nozzle reduces dripping and stringing.

VERSATILE USE: Fills a wide range of liquids into a wide assortment of containers.

SPEED UP OPERATIONS: Decrease the time between fills, and prevent over-pouring.

HANDS-FREE FILLING: Fill cycle is actuated by a foot pedal.

Downloads

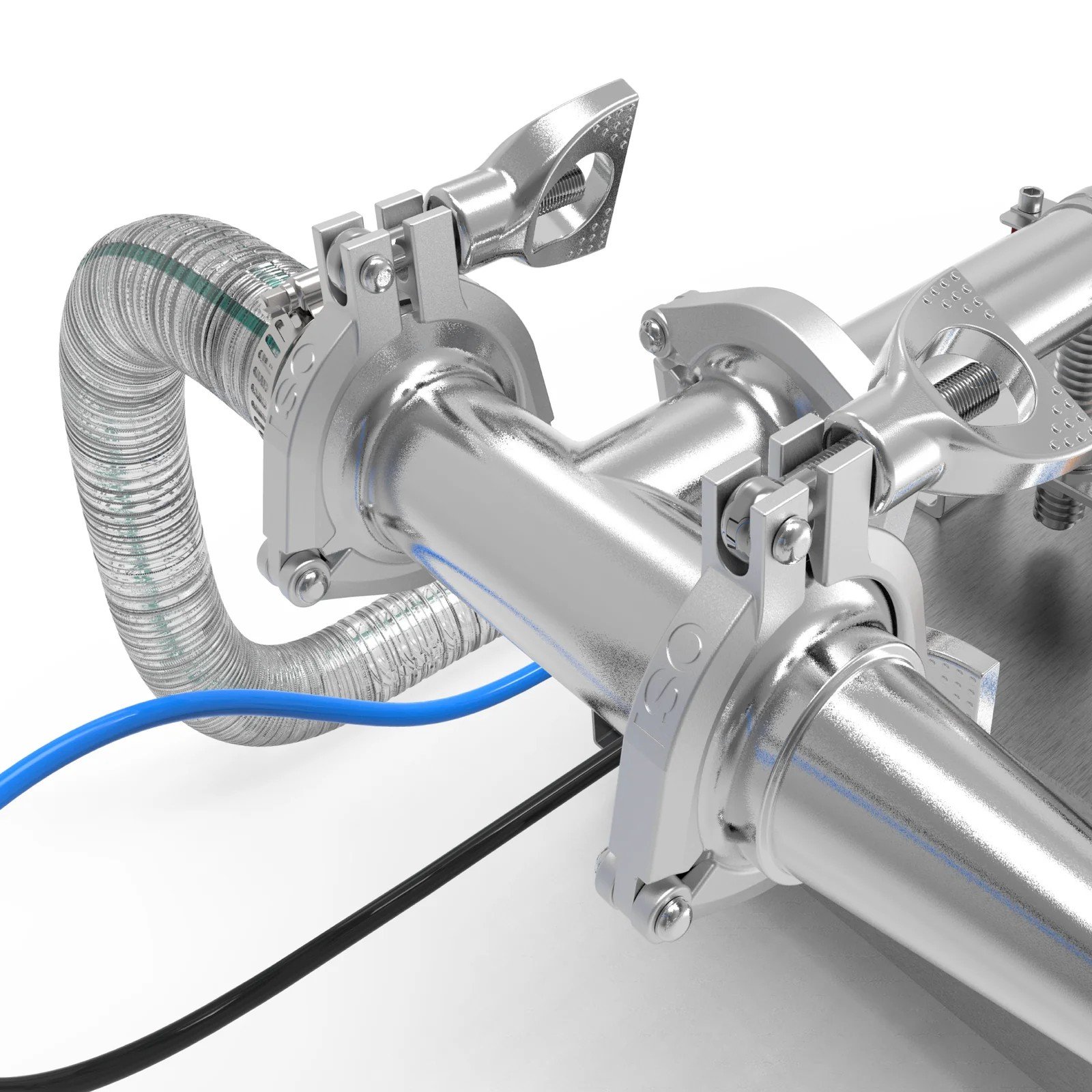

JoresTech High-Viscosity Piston Filler

High-accuracy affordable filler for paste/chunky fluids 50ml - 5000ml

Available in the following sizes: 50ml, 100ml, 250ml, 500ml, 1000ml, 5000ml - Follow the link below to buy now!

This volumetric piston filling machine from Jores Technologies can fill a variety of thick or chunky liquid products into bottles or containers. Ideal for startups, medium-volume production lines, and businesses looking to upgrade from manual filling, it is small in size and easy to operate. Its food-safe construction makes this a popular solution for handling beverages, cosmetic creams, salsas, oils, lotions, pastes, and much more.

Features:

316 Stainless Steel: Parts in contact with product are 316 SS.

304 SS shell.

EASY SETUP PROCESS: Machine adjustments are performed by simply turning a few small valves until desired settings are achieved.

PRECISE POURING: Once the machine is set to desired speed and quantity, the piston filler will dispense accurately and repeatedly.

EASY TO SANITIZE: Machine can be taken apart within minutes without the need for any additional tools.

STAINLESS STEEL BODY: Strong and long-lasting construction.

SMALL-SCALE CONSTRUCTION: Industrial-grade results in a small and compact machine.

LEAK PREVENTION: Anti-drip nozzle eliminates messy pouring practices.

VARIABLE FILLING RANGE: Provides flexibility and versatility.

PRODUCTION EFFICIENCY: Enhance your filling and packaging operations.

PEDAL ACTIVATION: Operated with a foot pedal for extra safety and control.

IDEAL FOR THICKER LIQUIDS: Suited for viscous products that are paste, semi-paste, and chunky with large particulates.

Downloads

Apex Tabletop Piston Filler

Affordable Semi-Automated Filling

Apex Tabletop Filler filling slime

Apex tabletop piston filler filling salsa

Overview: The Apex Tabletop Piston Filler is a semi-automatic unit designed for precise and consisten`t filling of liquids, creams, pastes, and other viscous products. Built for small to medium production runs, it provides flexibility, reliability, and accuracy in a compact footprint.

Features & Benefits:

Adjustable piston stroke for variable fill volumes

Ideal for small-batch producers and contract packagers

Simple setup and operation—minimal training required

Quick disassembly for cleaning and changeovers

Suitable for food, beverage, cosmetics, nutraceutical, and chemical industries

Key Specifications:

Filling Range: 15–1000 mL

Speed: Up to 25 containers per minute

Accuracy: ±1%

Power: Pneumatic operation (no electrical components)

Construction: Food-grade stainless steel with sanitary fittings

Design: Compact tabletop configuration, easily cleaned and maintained

Ideal Applications:

Perfect for small-scale producers looking to efficiently fill bottles, jars, and containers with consistent accuracy and minimal waste.

Downloads

Pack Leader FL-12 / FL-14

2- and 4- head automated filling

Pack Leader FL-12 filling hot sauce

Pack Leader FL-12 filling face cream

Overview: The FL-12 is a compact, fully automatic liquid filling machine designed for efficiency and precision in small- to medium-scale production. Built from S304 stainless steel with high-grade SS-316 filling pumps, it offers a clean, reliable, and easy-to-operate filling solution.

Features & Benefits:

Touchscreen control panel with memory presets for multiple products

Servo-driven system ensures precision filling with ±1% accuracy

Compatible with CP-10 capping and PL-series labeling machines for inline automation

Compact footprint ideal for limited production spaces

GMP & ISO 9001 compliant stainless-steel construction

Built-in jam sensor and variable-speed motor for smooth operation

Key Specifications:

Filling Range: 10–1000 mL

Filling Speed: 15–30 bottles per minute (depending on fill volume)

Filling Methods: Above liquid, underneath liquid, and bottleneck filling

Bottle Diameter: 20–100 mm

Bottle Height: 50–250 mm

Dimensions (L x W x H): 78.7” x 39.4” x 72.4” (2000mm x 1000mm x 1840mm)

Power: 220V, 1 Phase, 0.84 kW, Servo Motor

Net Weight: 330 lbs (150 kg)