Auger Fillers

For powders, granules, pastes or processed foods

Powered By:

Per-Fil Micro Filler

Affordable Semi-Automated Filling

Overview: The PER-FIL Micro-Filler is an entry-level auger filling system built for small to mid-volume production. Designed with small businesses in mind, it’s a plug-and-play system that’s easy to use, maintain, and customize for a wide range of products. With thousands of units operating in over 90 countries, the Micro-Filler is trusted for its simplicity, reliability, and long service life.

Features & Benefits:

Plug-and-play setup – arrives ready to run; minimal setup time

Dual Mode Control: Operates in Volumetric or Fill-by-Weight mode

Economical & Reliable: Perfect for growing businesses scaling from startup to higher-volume production

Easy Maintenance: “Off-the-shelf” parts with manufacturer part numbers listed in the manual

Custom Tooling: Configured for your product’s specific flow characteristics for optimal accuracy and speed

Comprehensive Support: Phone, email, video, and onsite assistance available worldwide

Key Specifications:

Fill Range: 1 g – 1 kg

Fill Accuracy: ±1.0% (test/video verification available)

Power Requirements: 120V / 220V, 50/60 Hz, 1 Phase

Cleanup & Changeover: Under 10 minutes

Drive System: Variable speed auger and agitator drive

Construction: Stainless steel NEMA 4 enclosure, IP68-rated controls

Made in USA: Designed, engineered, and manufactured domestically

Recommended Applications:

Ideal for food, chemical, cosmetic, pharmaceutical, and toner products.

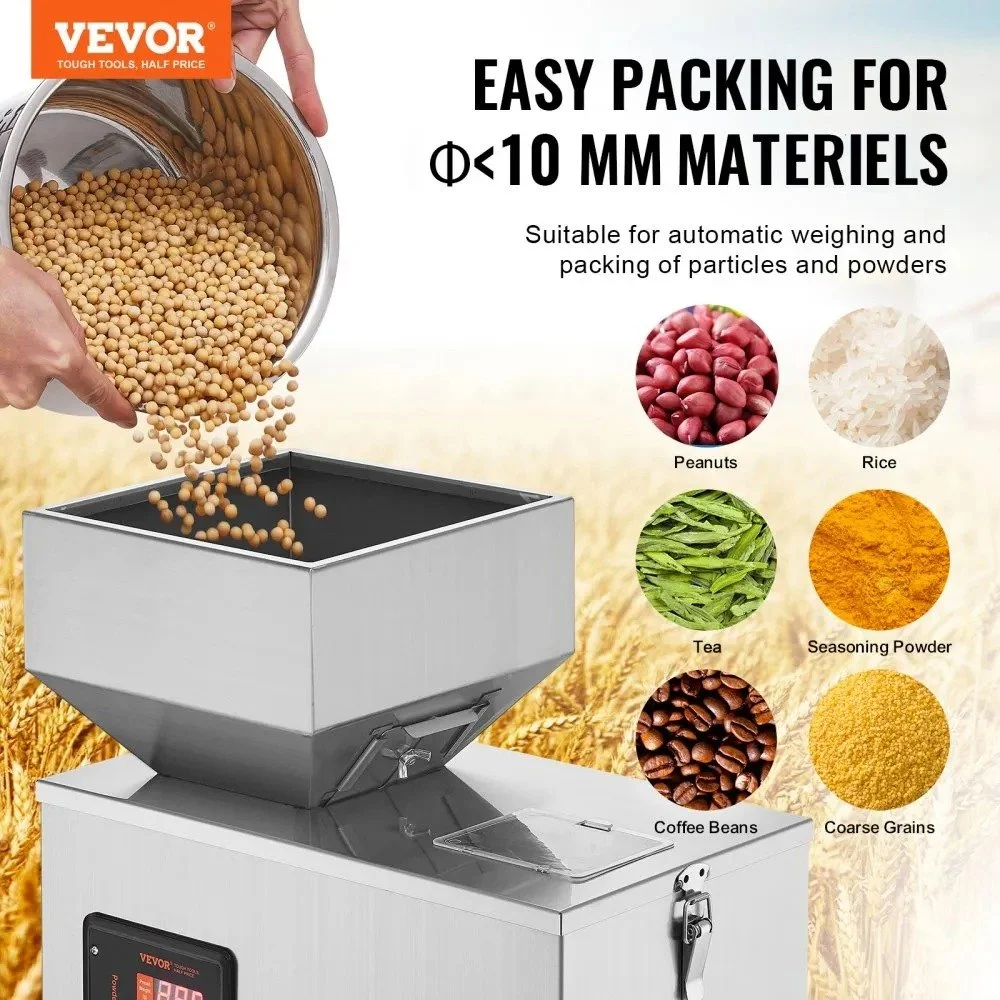

VEVOR Powder/Granule Filling Machine

Entry-Level Semi-Automated Filling

Available Models:

1g - 100g Fill Range - $152.99

1g - 200g Fill Range - $166.90

10g - 500g Fill Range - $259.99

Features & Details:

Fill with Ease: This automatic weighing filling packing machine handles particles up to Φ<10 mm, and it doesn't stop there! It effortlessly fills everything from seasoning powder to tea leaves and even grains.

Accurate Filling: With its built-in dual-stage vibration motor, this machine ensures accuracy within ±1 g. Fill anything from 1 g to 100 g effortlessly. Compared to single-vibration ones, the dual-vibration motor provides better discharge, avoiding any leftovers inside.

Intelligent Control: Take charge effortlessly! The automatic powder filling machine boasts an intelligent control panel, allowing you to adjust filling weights and speeds with ease for different materials. It's multifunctional and oh-so-easy to use.

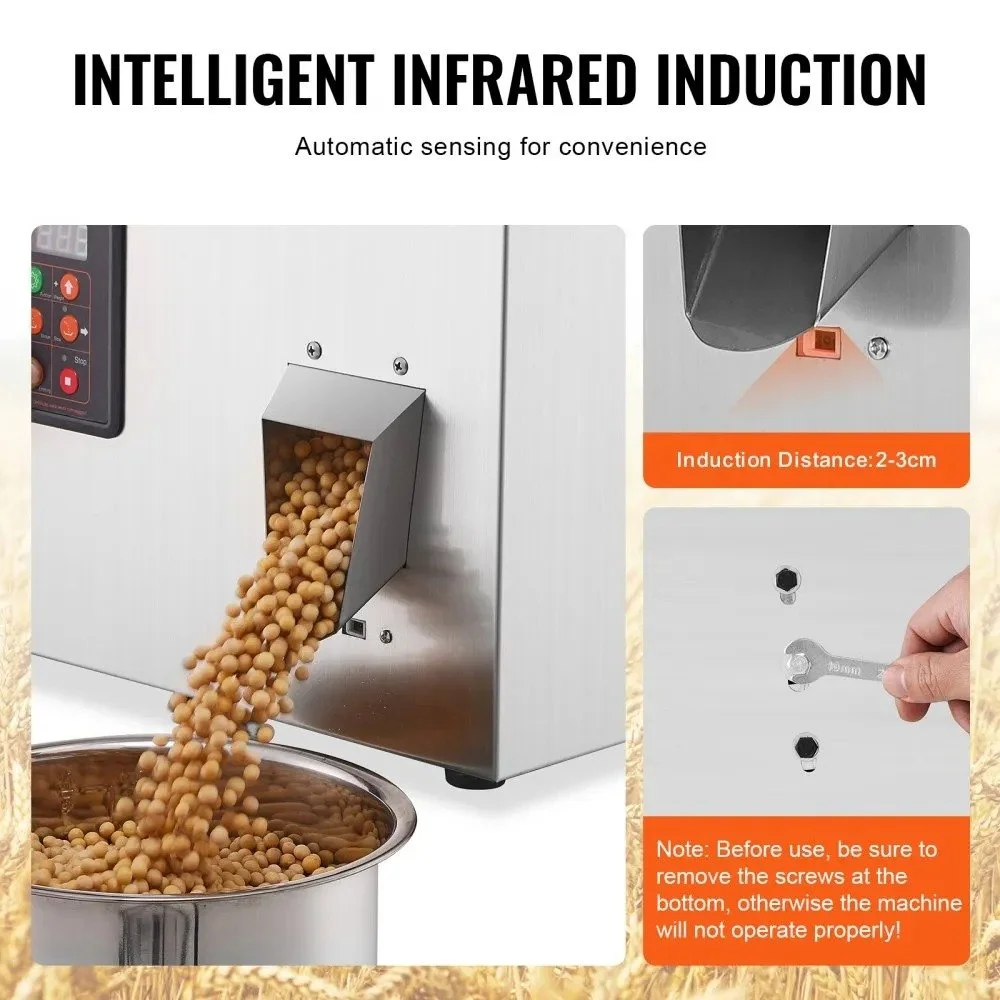

Sensitive Sensing: No more manual hassles! The powder packing machine's discharge port features an intelligent infrared sensing function, automatically detecting when to dispense without any need for switches.

Built Tough for Lasting Use: Crafted entirely from stainless steel, with key components (hopper/vibrating tray/weighing hopper/discharge port) made from food-grade 304 material, this unit ensures reliable performance and security with every fill.

Downloads

Downloads

Per-Fil Micro C

Upgrade the Micro Filler for a fully automated line

Overview:

The PER-FIL Micro-C is the automated version of the Original Micro-Filler, designed for small to mid-sized businesses ready to scale production. Operating in over 90 countries, the Micro-C delivers high-volume, economical automation with long-term reliability. It’s ideal for powders, granules, pastes, and processed foods.

Features & Benefits:

Economical Automation: Entry-level automatic filler offering exceptional value for small and growing producers.

Versatility: Handles fine powders and free-flowing granules on the same machine; custom tooling ensures optimal accuracy.

Easy to Use: Plug-and-play setup, no tools required for changeover.

Upgradeable: Add bulk feeders, checkweighers, cappers, labelers, or other equipment as production grows.

Proven Reliability: Maintenance-free operation and readily available off-the-shelf parts.

Global Support: Remote and onsite service in over 90 countries.

Key Specifications:

Filling Range: Custom-configured per application

Product Types: Powders, granules, pastes, and processed foods

Operation: Fully automatic, tool-free changeover

Recipes: 30 pre-programmed for quick setup

Construction: Durable stainless steel design, low maintenance

Average Service Life: 20+ years

Made in USA: Designed, engineered, and manufactured domestically

Ideal Applications:

Perfect for food, cosmetic, and nutraceutical producers seeking dependable, automated filling with minimal maintenance and high throughput.