Top and Bottom Labelers

Works with trays, boxes, clamshells, chipboard containers, bags and even caps on bottles!

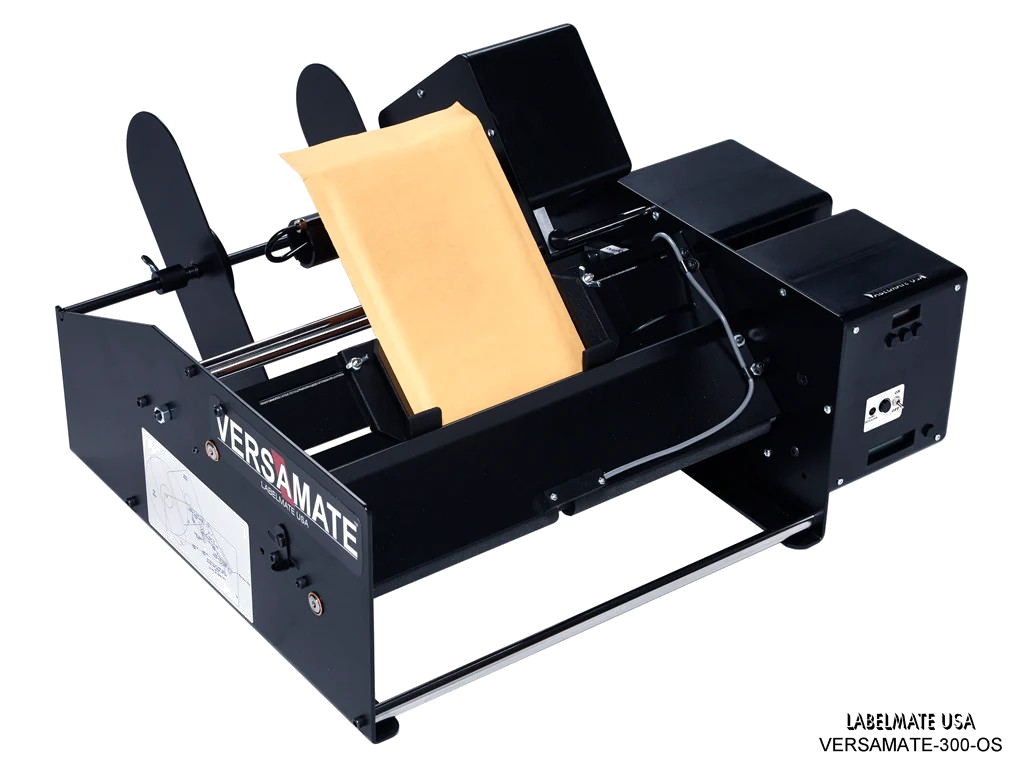

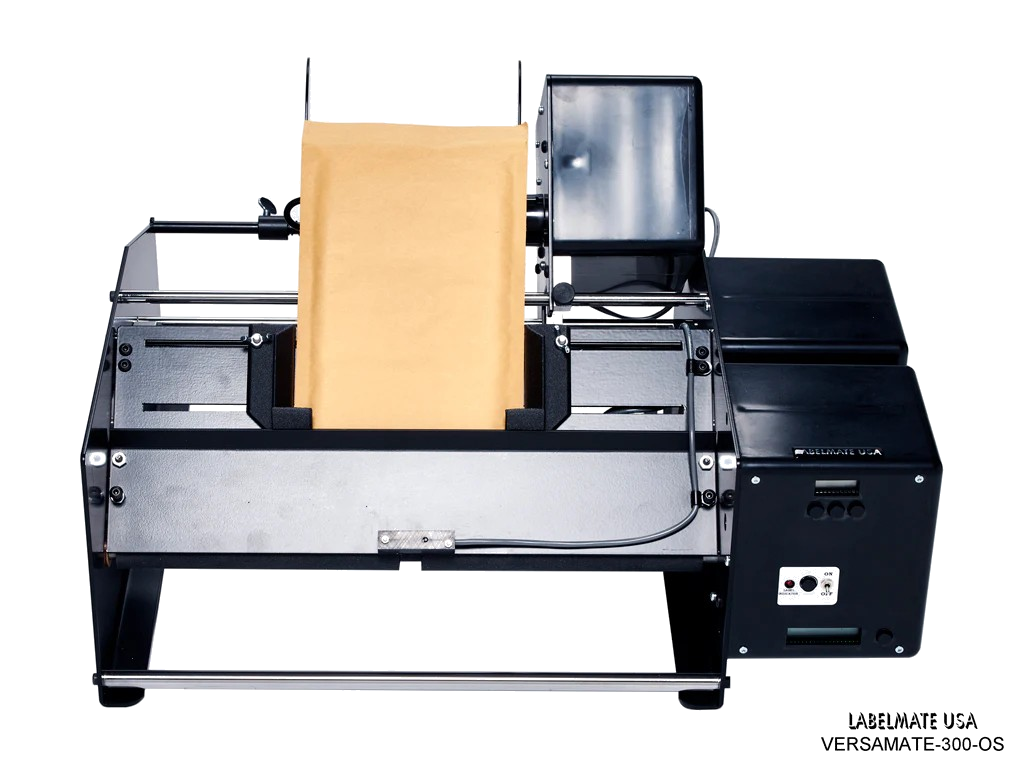

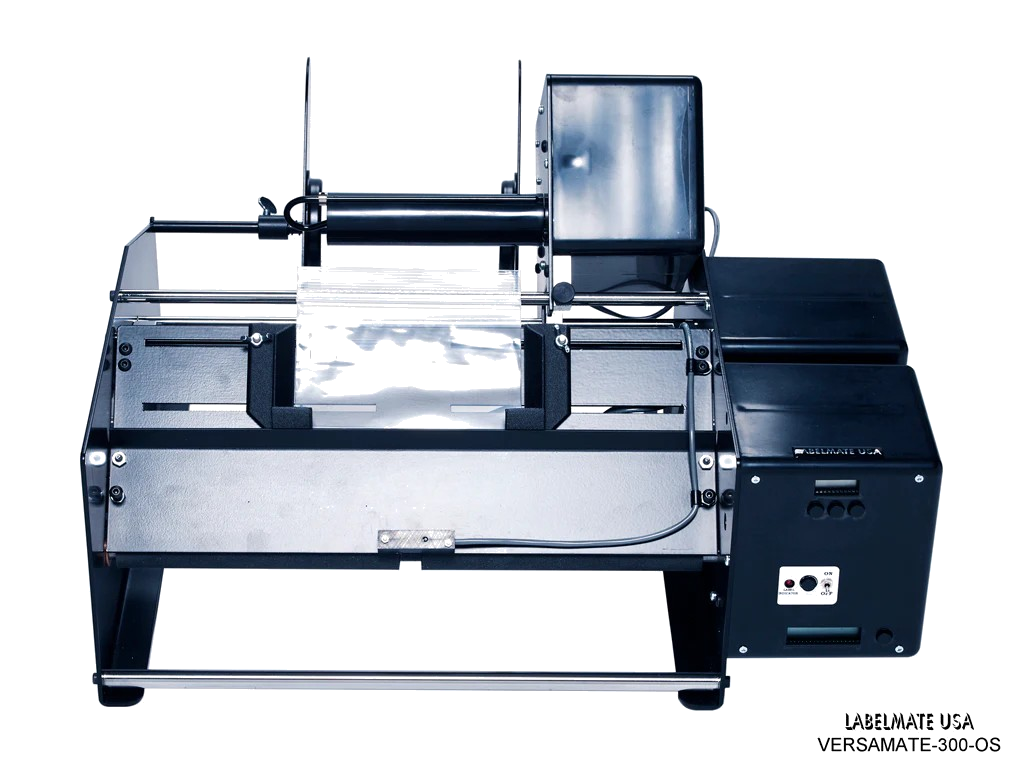

Label Mate VERSATMATE-300-OS

Entry-level automated label applicator for flat packages

Automatic Label Applicator (Opaque Labels) with Optical Sensor for bags and other flat items.

Description: The VERSAMATE-300-OS is the optimum desktop solution for automatically applying labels to flat items. Simply insert your bag/envelope and watch as labels are repeatedly applied in the same location every time.

This Label Applicator accurately and consistently labels all of your flat items such as pouches, bags, envelopes, etc. Labels are applied at over 4.5” (114mm) per second, and most items are labeled in less than 3 seconds. Once a rhythm is established, you can label items at speeds of up to 1,200 pcs per hour.

Label Type: Opaque

Max. Label Width: 11.5” (292mm)

Max. Item Thickness: 0.20” (5mm)

Min. Label Length: 1” (25mm)

Max. Label Roll Diameter: 9” (230mm)

Includes the BMR-6 Waste Liner Rewinder

Warranty: 3-Year Parts & Labor Limited Warranty

Downloads

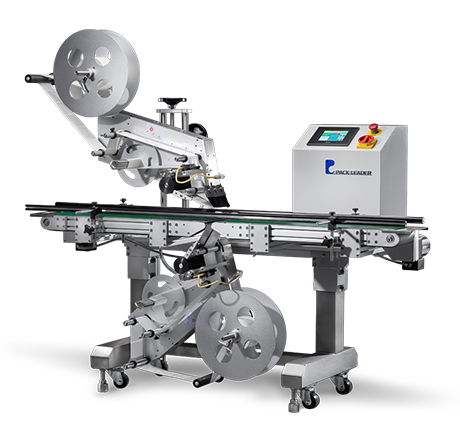

Pack Leader ELF-20

Fully automated top labeller at an affordable price

Overview:

The ELF-20 is a portable top labeling machine designed for small production runs. Its compact size and ease of use make it ideal for startups and small businesses looking to automate their labeling process.

Features:

Portability: Can be positioned on a tabletop or bench, or moved in-line for automatic or semi-automatic applications.

User-Friendly: One-button teach product and label sensors; manual position setting for accurate label placement.

Upgradable: Can be upgraded to activate hot-foil printer controls for label customization.

Productivity Features: Production preset function, label count feature, and container/production run counter.

Memory Retention: Battery-free microprocessor control system that maintains default settings and memory even after the machine sits idle for a long period.

Durability: Made of 304 stainless steel and anodized aluminum, ensuring longevity and compliance with Good Manufacturing Practices (GMP) standards.

Ideal Applications:

Perfect for small-scale production in industries such as food, beverage, cosmetics, and pharmaceuticals.

Key Specifications:

Label Type: Top

Maximum Dispensing Speed: 52.5 ft/min (16 m/min), 60 containers/min

Maximum Conveyor Speed: 52.5 ft/min (16 m/min), 60 containers/min

Dimensions (L x W x H): 43.3” x 20” x 35” (1100mm x 508mm x 889mm)

Maximum Label Size: 4.75” x 11.8” (120mm x 300mm)

Maximum Container Width: 6” (152.4mm)

Maximum Container Height: 4.75” (Flat 120mm)

Conveyor Width: 6” (152.4mm)

Spool Diameter: 10” (254mm)

Inner Core: 3” (76mm)

Power: 110/220 VAC, 50/60 Hz, 1 Phase; 0.400 kW; 2 Phase Stepper Motor

Net Weight: Approx. 132 lbs (60 kgs)

Downloads

PL-211

High-speed application for top labels up to 6”

Overview:

The PL-211 is a versatile top-labeling machine designed to efficiently apply labels to the tops of products, including trays, boxes, chipboard containers, bags, and even bottle caps. Its straightforward design, portability, and user-friendly controls make it ideal for small to medium production environments.

Features:

Easy to Use: One-button teach product and label sensors; manual position adjustments for precise labeling.

Flexible: Can be used for in-line automatic or semi-automatic applications.

Durable: 304 stainless steel and anodized aluminum construction; GMP and ISO 9001 compliant.

Accuracy & Productivity: Stepper motor ensures precise label placement; features auto label-set, missing label detection, production preset, and container run counters.

Portability: Can be easily moved to other production areas; height-adjustable conveyor.

Upgradeable: Compatible with thermal or hot foil printer controls for label customization.

Ideal Applications:

Perfect for top labeling of a variety of products in food, beverage, cosmetics, and pharmaceutical industries, especially for small- to medium-scale production setups.

Key Specifications:

Label Type: Top (wrap-around clamshell optional)

Maximum Dispensing Speed: 131.2 ft/min (40 m/min)

Maximum Conveyor Speed: 131.2 ft/min (40 m/min)

Dimensions (L x W x H): 50.5” x 29.5” x 62” (1283mm x 750mm x 1575mm)

Maximum Label Size: 6” x 11.8” (152mm x 300mm)

Maximum Container Width: 8.5” (216mm)

Maximum Container Height: 7.5” (Flat 191mm)

Conveyor Width: 6.25” (159mm), optional widths available

Conveyor Height: 29.5–39.5” (749–1003mm)

Spool Diameter: 14” (356mm)

Inner Core: 3” (76mm)

Voltage: 110/220 VAC, 50/60 Hz, 1 Phase

Power: 0.700 kW

Drive: Stepper Motor

Net Weight: Approx. 265 lbs (120 kg)

Controls: Delta Color Touch Screen

Downloads

PL-221

High-speed top-and-bottom application for labels up to 6”

Overview:

The PL-221 is a dual-head labeling machine that simultaneously applies labels to the top and bottom of products in a single pass. Its compact, durable design and user-friendly interface make it ideal for small- to medium-scale production in industries such as food, beverage, cosmetics, and pharmaceuticals.

Features:

Flexible & Accurate: One-button teach product and label sensors; manual position adjustment for precise label placement.

Upgradeable: Compatible with thermal or hot foil printer controls for date coding or custom labeling.

Productivity Features: Production preset, label count, container/production run counter.

Memory Retention: Battery-free microprocessor maintains default settings even after long idle periods.

Efficiency & Safety: Auto label-set, missing label detection, synchronized stepper motor for accurate labeling.

Portability: Height-adjustable conveyor, can be easily moved for different production layouts.

Durability & Compliance: Made of 304 stainless steel and anodized aluminum; compliant with GMP and ISO 9001 standards.

Ideal Applications:

Top and bottom labeling for cylindrical or rectangular products in food, beverage, cosmetics, and pharmaceutical production.

Key Specifications:

Label Type: Top & Bottom

Maximum Dispensing Speed: 131.2 ft/min (40 m/min)

Maximum Conveyor Speed: 131.2 ft/min (40 m/min)

Dimensions (L x W x H): 68.75” x 32” x 66” (1746mm x 813mm x 1676mm)

Maximum Label Size: 6” x 11.8” (152mm x 300mm)

Maximum Container Width: 6.5” (165mm)

Maximum Container Height: 6” (152mm)

Conveyor Width: 6.25” (159mm)

Spool Diameter: 14” (356mm)

Inner Core: 3” (76mm)

Conveyor Height: 29.5–39.5” (749–1003mm)

Power: 110/220 VAC, 50/60 Hz, 1 Phase, 0.825 kW, Stepper Motor

Net Weight: Approx. 265 lbs (120 kg)